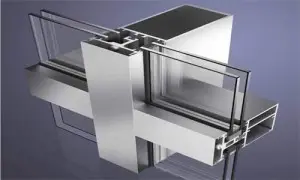

Aluminum sheet curtain wall adopts high quality and high strength aluminum alloy sheet, its common thickness is 1.5, 2, 2.5, 3.0MM, and the model is 3003, and the state is H24. Its structure is mainly composed of a panel, stiffener and bracket component. Code can be directly by the panel bending, stamping molding, but also in the small side panel on riveting corner molding. The stiffener and the welding screws after the plate surface (the screws are directly welded on the back of the panel) are connected to make them become a solid whole, which greatly enhances the strength and rigidity of the aluminum veneer curtain wall, and ensures the smoothness and wind resistance and anti-seismic capability of the long-term use. If the sound insulation is needed, a high efficient sound insulation material can be installed on the inside of the aluminum plate.

The surface of the aluminum plate curtain wall is usually treated by chromizing and other pretreatment, and then the fluorocarbon spray is used. Polyvinylidene fluoroethylene resin (KANAR500) for fluorocarbon paint and varnish. It is generally divided into two, three or four. Fluorocarbon coating has excellent corrosion resistance and weatherability. It can resist acid rain, salt spray and various air pollutants. It has excellent cold and heat resistance. It can resist strong ultraviolet radiation, and it can keep color free, non powdery and long service life in a long time.

The aluminum sheet curtain wall is of good steel, light weight and high strength.

The aluminum sheet curtain wall plate has good corrosion resistance, and the fluorocarbon paint can not fade for 25 years. The aluminium plate curtain wall is very technical. With the first finishing process, the aluminum plate can be machined into a variety of complex geometric shapes, such as plane, arc and spherical surface. The aluminum plate curtain wall is not easy to be tarnished, so it is easy to clean and maintain. The non stickiness of the fluorine coating film makes it difficult to attach the surface to the contaminants, and it is better to be clean. The installation and construction of aluminum plate curtain wall is convenient and quick. The aluminum plate is formed in the factory, and the construction site needs not to be cut but simply fixed. The aluminum plate curtain wall can be recycled and reused, which is favorable for environmental protection. The aluminum plate can be recycled 100%, and the recovery value is higher.

Aluminum curtain wall has unique texture, rich color and lasting, and its appearance and shape can be diversified, and it can perfectly integrate with glass curtain wall materials and stone curtain wall materials. Its perfect appearance and excellent quality make it much favored by the owners. Its weight is light, only 1/5 of the marble, 1/3 of the glass curtain wall, which greatly reduces the load of the building structure and foundation, and has low maintenance cost and high performance price ratio.

Media Contact

Company Name: Sichuan Zlinkage Technology Co., Ltd.

Email: Send Email

Country: China

Website: https://www.zlinkage-metal.com/