FCE is honored to collaborate with Strella, a trailblazing biotechnology company dedicated to addressing the global challenge of food waste. With over one-third of the world’s food supply wasted before consumption, Strella tackles this problem head-on by developing cutting-edge gas monitoring sensors. These sensors are utilized in agricultural warehouses, transportation containers, and supermarkets to predict the shelf life of fresh produce, ensuring it stays fresh longer and reducing unnecessary waste.

Strella’s Advanced Sensor Technology

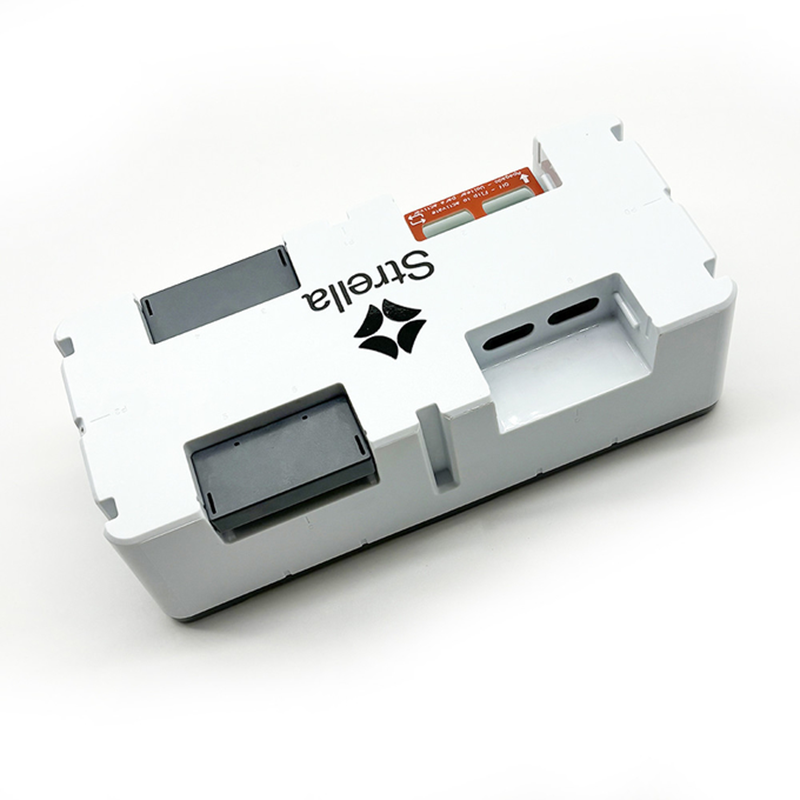

Strella’s sensors rely on highly precise components, such as antennas, oxygen sensors, and carbon dioxide sensors, to monitor gas levels. By detecting environmental changes in storage areas, these sensors help assess the freshness of agricultural products. Given the complex functionality of these sensors, they demand superior sealing and waterproofing capabilities, making design stability and consistent production essential to their performance.

FCE’s All-in-One Manufacturing Solutions

FCE’s collaboration with Strella extends well beyond simple component manufacturing. We provide an end-to-end assembly solution, ensuring that each sensor is fully assembled, programmed, tested, and delivered in its final form. This comprehensive approach ensures that every sensor meets Strella’s stringent quality and performance benchmarks.

From the outset, FCE conducted detailed analyses on component feasibility and tolerances to optimize designs for efficient assembly and high yield rates. We worked closely with Strella to fine-tune the functionality and aesthetics of each part. Additionally, we conducted a thorough Failure Mode and Effects Analysis (FMEA) to minimize potential issues during assembly.

Optimized Assembly Process

To meet the high standards required by Strella’s sensors, FCE set up a customized assembly line equipped with state-of-the-art tools, such as electric screwdrivers with calibrated torque settings, customized test fixtures, programming devices, and testing computers. Every stage of the assembly process was fine-tuned to reduce errors and increase first-pass yield rates.

Each sensor produced by FCE is uniquely coded, and all production data is carefully tracked, ensuring full traceability for every unit. This provides Strella with a valuable resource for future maintenance or troubleshooting, ensuring reliability and long-term performance.

A Successful, Lasting Partnership

Over the last three years, FCE and Strella have formed a robust partnership. FCE has consistently delivered high-quality solutions, from material selection and functional optimization to structural refinement and packaging. This close collaboration resulted in Strella awarding FCE their Best Supplier accolade, recognizing our dedication to innovation, quality, and sustainability.

By working together, FCE and Strella are making meaningful strides in the fight against global food waste, combining technological innovation with a commitment to quality for a more sustainable future.

Media Contact

Company Name: FCE

Email: Send Email

Country: China

Website: https://www.fcemolding.com/