Carbon fiber is a lightweight, yet durable material used for aerospace and automotive applications. It’s also helpful in many other industries such as wind power generation or sports equipment manufacturing because of its strength-to-weight ratio. When it comes to cutting carbon fiber, there are a variety of options. Laser cutting is a great way to cut carbon fiber since it is so flexible and effective. Carbon fiber laser cutting has a lot of promise in numerous sectors because of its high cutting speed and outstanding cutting precision. The benefits of laser cutting are not just short-term. The laser technology has helped carbon fiber processing enterprises establish themselves in the market, and will continue to do so as they have long term potential for growth. And it could even lead to new line extensions and brand recognition. In this blog post, we are going to explore some of the advantages of carbon fiber laser cutting, the processing technology as well as its application prospects.

Introduction of carbon fiber

Carbon Fiber, often known as graphite fiber, is a polymer. It is an extremely robust and lightweight material. Carbon fiber topped many engineers’ lists as the ideal manufacturing material because of its properties including high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion. These properties of carbon fiber have made it very popular in a variety of industries, including aerospace, automotive and engineering to name just some – but its use is not limited to these fields; you can find this high performance material being used for everything from civil construction projects such as bridges or aircrafts (such as the Airbus) through motorsports like Formula One racing cars.

Benefits of laser cutting carbon fiber over other technologies

Due to assembly requirements, it is often necessary to process carbon fibers such as cutting. Traditional processing methods include machining methods such as turning, milling, grinding, and drilling. Carbon fiber has the characteristics of high strength and high brittleness. If the tool is not selected properly using traditional machining methods, it will accelerate tool wear, increase cost, and easily lead to material cracks and deformation. Especially when the carbon fiber is drilled with small holes, it is more likely to cause poor processing or even scrapping of the material. The laser cutting is a non-contact processing method, which can solve the problems encountered in the carbon fiber processing process.

Becsuse of the nature of the material, the cutting carbon fiber brings significant challenges to engineering firms in terms of obtaining precise and consistent results as compared to machining traditional materials such as fabric and leather. Laser cutting of carbon fiber is a process that has many advantages. The process can be done with a CO2 laser, which uses minimal energy but offers high quality results. Carbon fiber is created by combining two materials: polyacrylonitrile and resin. However, laser cutting allows for more precise cuts than traditional methods such as plasma and water jet cutters. The processing technology of laser cutting carbon fiber also helps with reducing scrap rates when compared to other production techniques. For example, when using the aforementioned processes, if the material is not perfectly aligned on the table then it cannot be cut in one piece; this results in wasted materials which can cost hundreds of dollars per hour of lost production time!

Laser cutting carbon fiber is the best way to get all of the benefits for this material. It can process any type of thickness and shape with great precision, it’s very quick, and there are no fumes or dust particles that need to be dealt with. Laser cutting carbon fiber has many advantages over other types of processing technology due to its speed, versatility in dealing with different shapes and thicknesses, lack of harmful fumes or particles when working on it. The smaller laser cut pieces will also fit into tighter spaces than a saw blade might allow for giving more flexibility in design work. This new technology also allows you to create intricate designs which would otherwise be impossible using older methods such as plasma or water jet cutting without adding extra time.

Application industries of carbon fiber laser cutting

1. Carbon fiber laser cutting in the aerospace industry

Carbon fiber is a wonder material that has revolutionized the way we make our aviation, space and automotive parts. Compared with metal materials like steel, it’s lighter weight allows for greater fuel efficiency while reducing CO2 emissions. Laser cutting machines are cutting-edge tools for the manufacturing industry. They allow manufacturers to produce high quality products in record time with little waste and minimal labor hours spent on production, which can save costs thousands fold over traditional methods of making things like airplanes or parts thereof! For example: avionics panels on an airplane might be made from lightweight carbon fiber using a CO2 laser cutter – this produces incredibly accurate cuts that could not easily have been accomplished by traditional cutting tools due both its difficulty with accuracy as well as volume necessary per order.

2. Carbon fiber laser cutting in the automotive industry

Laser cutting technology has always been used by industries such as aerospace which require extreme accuracy when fabricating complex shapes. The same kind of precision can now take place on cars thanks not only to improvements within manufacturing processes but also product design changes.

In the automotive manufacturing sector, laser cutting machines have been employed to cut carbon fiber to build structural components, covering parts, interior parts, and body for automobile production. Laser cutting has become an integral part in the manufacturing process for vehicles. Since lasers can produce extremely high precision cuts and parts made from carbon fiber are incredibly strong despite their lightweight nature (which makes them ideal), this technology offers great potential when it comes to design ideas.

Laser cutting carbon fiber for auto parts will get more popular as it meets higher environmental standards today – many people are turning their attention to light vehicles that utilize these efficient materials like never before!

3. Carbon fiber laser cutting in the sports industry

Laser cutting technology is also an excellent tool for the production of sports goods. The laser cut carbon fiber can produce many types and varieties, which are very popular among athletes because it provides them with greater durability than traditional materials or equipment would do so.

We all know that carbon fiber is lightweight and durable, but you might not have known it can be used to make light sports equipment. Laser cutting makes this possible with many different kinds of goods for our daily lives! For example: rackets or skis from the club house.

Just think about how many opportunities there are for laser cut carbon fiber sports goods! From rackets and skis to bikes and helmets, this material is versatile in its application. Imagine a day when you can have your equipment custom made from lightweight but strong materials like those found on your favorite athlete’s personas – it would make playing outdoors all that much more fun.

4. Carbon fiber laser cutting in the medical industry

Medical equipment can be made from carbon fiber to reduce weight, increase strength and durability. Medical professionals should always ensure that their materials are high-quality so they don’t negatively affect patients inside medical facilities or while traveling outside of them

With advances in technology we have seen an incredible rise not only in technological creations but also innovations like those utilizing composite plastics which use laser cutting as one such method for manufacturing these products by combining a range of different types into single item – this instance being something designed specifically around healthcare needs! According there’s been quite significant growth over recent years when considering both demand.

Laser cutting is a process that creates extremely detailed cuts, holes and shapes with high precision. The speeds at which laser cut parts can be produced make it an efficient method for manufacturing medical equipment structural components such as X-ray tables or booms; this compared to other methods like waterjetting whose output may not always meet the accuracy requirements needed by these devices due their lack of detail (and therefore size).

Conclusion

Carbon fibre is an advanced basic material and a key strategic material that restricts the development of manufacturing industry. Its upstream and downstream industrial chains are extremely important for reconstructing the new material industry system, with practical and potential applications in aerospace, rail transportation, marine vehicles, bridge construction, power tools, power cables, pressure vessels, sports equipment, wind power engines, fuel cells, special tube and barrels, medical and industrial equipment.

As the cost of carbon fiber decreases and the application level further matures, carbon fiber composites will usher in a large explosive growth in industry and civil use, and laser processing of carbon fiber materials will certainly become a new application of laser processing.

Laser cutting is a new and innovative way to cut carbon fibers. industrial CO2 laser cutter can cut through carbon fibers with ease because it does so without abrasion or distortion. Thus the efficiency of the cutting process will increase greatly without any worries about damaging or harmful effects on materials being processed by this method.

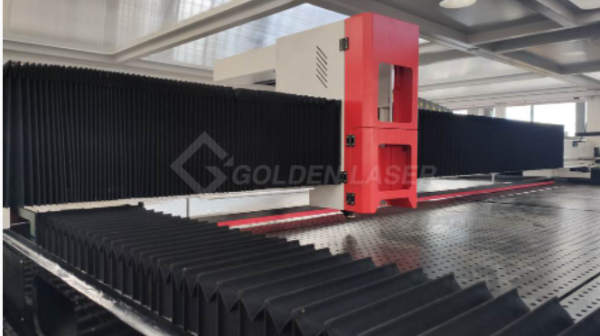

If consumers are interested in finding out more about how laser cutting machines work or want one installed at your facility, Contact Goldenlaser Today!

Media Contact

Company Name: Wuhan Golden Laser Co., Ltd.

Email: Send Email

Phone: +86 158 027 39301

Country: China

Website: https://www.goldenfiberlaser.com/