1. Application of Samarium Cobalt in Petroleum Industry

SmCo magnets, as a high-performance rare earth permanent magnet materials, have excellent high temperature resistance, corrosion resistance and high magnetic properties, especially in high temperature, high pressure and corrosive environments. . Samarium cobalt magnets are widely used in petroleum industry equipment, such as: Logging Tools, magnetic pumps and valves, Downhole Turbines, bearingless drilling motors, magnetic separation equipment, etc. According to industry estimates, the market size of samarium cobalt magnets in the petroleum field accounts for approximately 10%-15% of the total global samarium cobalt magnet market, with an annual market value of approximately US$500 million to US$1,000 million. As more oil companies expand into complex geological environments and the demand for reliable and high-performance equipment grows, the market potential of samarium cobalt magnets in the oil industry may further expand.

2. Why are SmCo magnet more suitable for the petroleum industry?

SmCo magnets have remarkable adaptability in the petroleum industry. SmCo magnet have good adaptability and high fit in petroleum application scenarios where high temperature, high pressure, and corrosive environments are common, ensuring efficient and stable operation of equipment and improving the efficiency and effectiveness of all aspects of oil extraction. reliability. The following are the advantages of samarium cobalt magnets in the petroleum industry:

2.1. High temperature resistance performance requirements

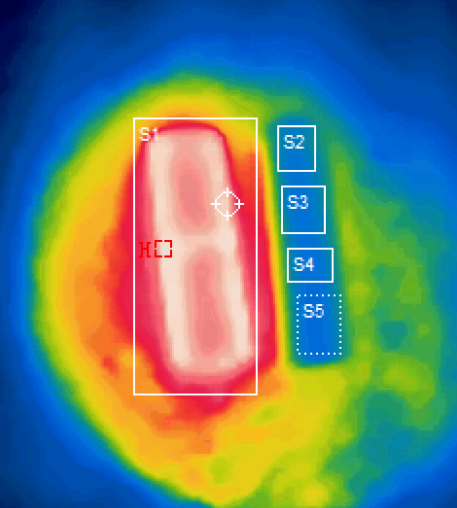

The increase in the depth of oil exploration and production will cause the underground temperature to rise. For example, when mining in deep and ultra-deep oil reservoirs, the ambient temperature of the logging equipment often exceeds 300°C. SmCo magnets have a high Curie temperature, and the T series ultra-high temperature SmCo has a maximum operating temperature of 550°C. This feature ensures that samarium cobalt magnets can maintain stable magnetic properties in high temperature environments, ensure accurate magnetic positioning, and accurately control the direction of drilling tools. It improves mining efficiency and success rate, reduces geological risks, and also provides reliable support for reserve assessment and mining plan planning.

2.2. High magnetic energy product requirements

In equipment such as magnetic pumps and bearingless drilling motors, the high magnetic energy products of samarium cobalt magnets is indispensable. The magnetic pump uses high magnetic energy product to generate a strong magnetic field to drive the impeller, achieving leakage-free transportation and preventing oil leakage pollution and safety hazards; the bearingless drilling motor relies on it to provide a strong magnetic field force to support the stable suspension operation of the rotor, reduce friction loss, and extend the life of the equipment. Reduce maintenance frequency and costs to ensure continuous and efficient advancement of drilling operations.

2.3. Corrosion resistance requirements

Oil production and transportation contain a variety of corrosive media. Offshore platforms are corroded by seawater salt and acidic gases, and onshore oil fields are also threatened by corrosion such as H₂S and halogen ions. In equipment such as magnetic separation equipment and downhole instruments that are exposed to corrosive environments for a long time, samarium cobalt magnets must have stable structure and performance. They must be resistant to H₂S and halogen corrosion under the protection of special coatings, maintain equipment integrity and functional stability, and ensure the quality of crude oil. Reduce equipment loss and replacement costs, improve production safety and economic benefits, and lay a solid foundation for long-term stable production.

3. Advantages of samarium cobalt magnets-magnetic cohesion

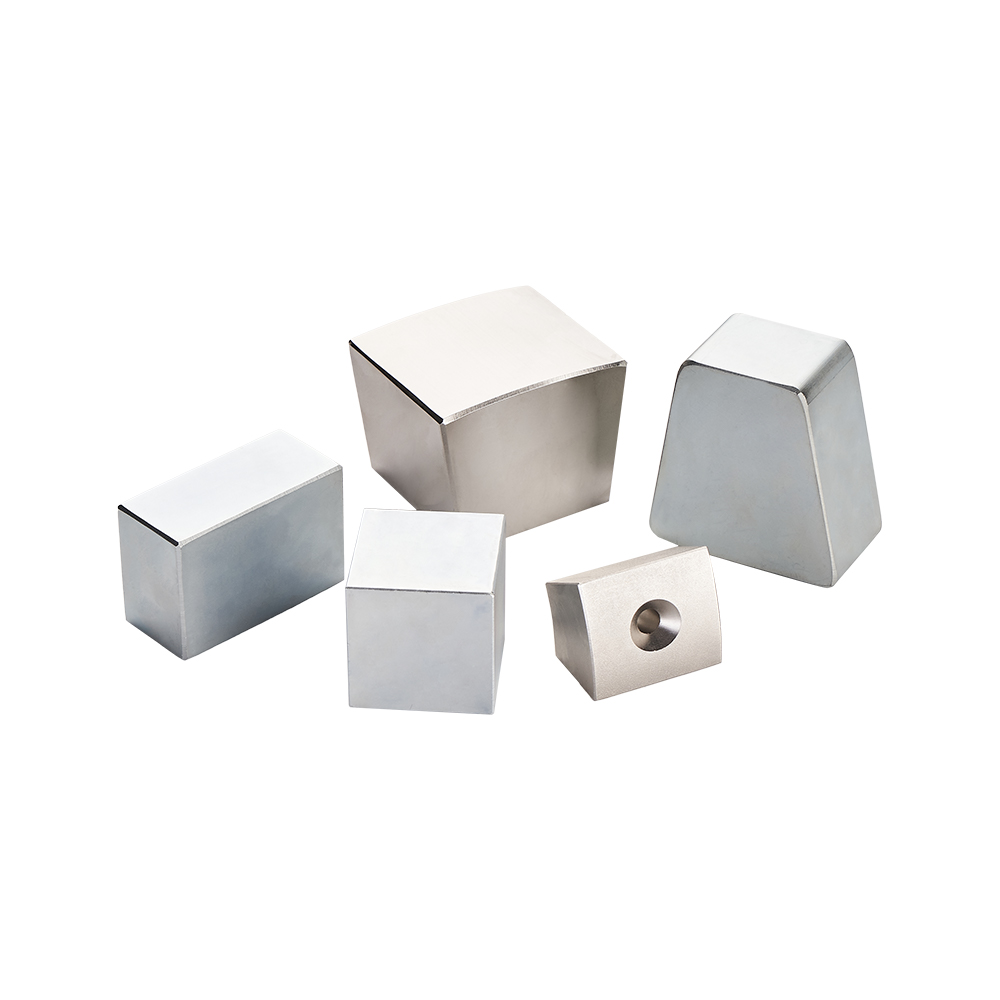

Hangzhou Magnet Power Technology Co., Ltd. has emerged strongly in the samarium cobalt magnet field with its strong R&D and production team. The company’s carefully developed samarium cobalt magnet products have excellent performance in terms of high-temperature resistance and corrosion resistance, providing stable, solid and reliable samarium cobalt products for equipment in many industries, especially the petroleum industry.

T Series: Customized High Temperature Solutions

The T series samarium cobalt magnets developed by Magnet Power have excellent high temperature resistance and the maximum operating temperature can reach 550°C. The T series samarium cobalt magnets can still maintain stable operation in high-temperature environments such as underground measurement and for drilling equipment. Magnetic cohesion has a unique series at 350℃-550℃. In this temperature range, customized data calculation and production can be carried out according to the size, performance and usage scenarios of different needs of users. On the premise of meeting user needs to the maximum extent, it is guaranteed to Product stability during use.

H series: high magnetic energy product and stability

H series samarium cobalt magnets can guarantee a temperature resistance of 300℃ – 350℃. The coercive force of up to ≥18kOe ensures the stability of the magnetic properties of the product in high-temperature environments and effectively curbs thermal disturbance of magnetic domains. At the same time, it provides a high magnetic energy density of 28MGOe – 33MGOe, ensuring that the device has strong power during use. In the magnetic levitation architecture, the stable magnetic field supports the high-speed and smooth operation of the rotor, minimizing equipment friction loss and equipment failure rate, extending the equipment service life, and providing efficient and stable core power for oil extraction operations.

Corrosion resistance

In the complex working conditions of the petroleum industry, threats such as H₂S corrosion and halogen-induced corrosion are always present. Especially in high-corrosion scenarios such as sour oil and gas fields and around offshore platforms, equipment corrosion losses are severe. Hangzhou Magnet Power Technology Co., Ltd.’s samarium cobalt magnet steel products maintain their inherent corrosion resistance and can provide various special coatings to resist corrosion attacks. For example: when oil field magnetic separation equipment is immersed in corrosive liquid for a long time, special coatings can effectively resist the attack of H₂S and halogen ions, ensuring the stability of the magnetic steel structure and magnetic field; the samarium cobalt magnet produced by magnetic condensation has excellent corrosion resistance It provides long-term stable, high-performance permanent magnet products for the petroleum industry.

In the field of SmCo magnets, Hangzhou Magnet Power Technology Co., Ltd., with its ultimate performance advantages of high temperature resistance and corrosion resistance, deeply meets the equipment needs of the petroleum industry. With its products, from exploration to mining, from transmission to refining, it provides comprehensive assistance to the petroleum industry.Improve equipment performance, optimize operating procedures, reduce operational risks, and provide strong power and solid support for the development of the petroleum industry with excellent samarium cobalt magnet products.

Media Contact

Company Name: Hangzhou Magnet Power Technology Co., Ltd.

Email: Send Email

Country: China

Website: https://www.magnetpower-tech.com/