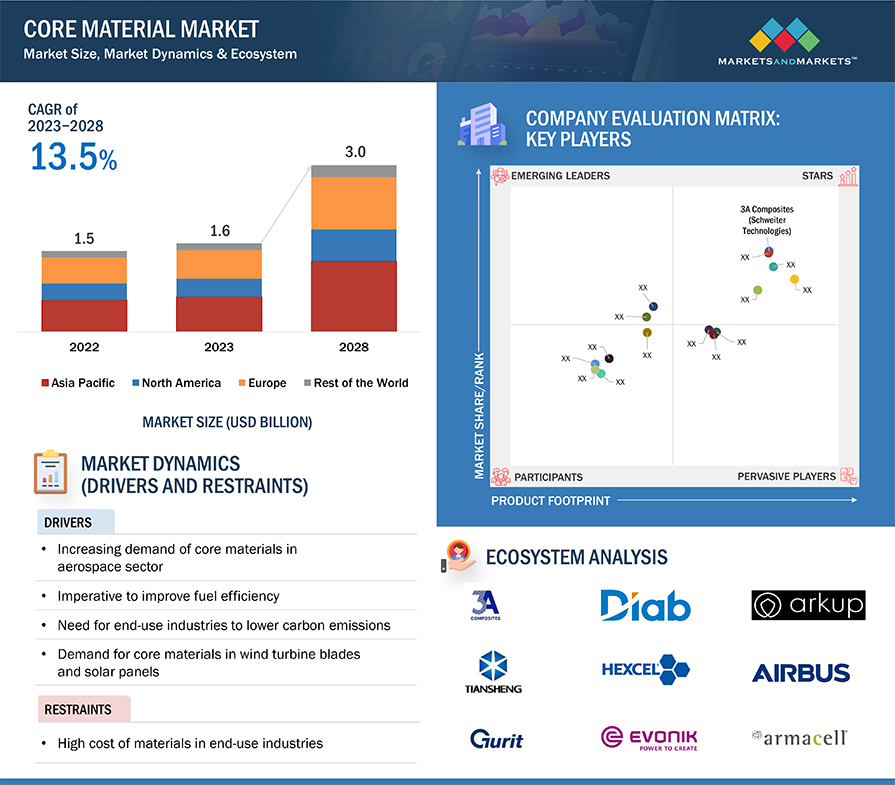

The report “Core Materials Market by Type (Foam, Balsa, and Honeycomb), End- use Industry (Wind Energy, Marine, Aerospace & Defense, Automotive & Transportation, Construction & Industrial), and Region – Global Forecast to 2028″, size is 1.6 billion in 2023 and is estimated to reach USD 3.0 billion by 2028, at a CAGR of 13.5%, during the forecast period.

Core materials such as foam, honeycomb and balsa are used in composite structures. Due to an increase in demand from the aerospace and defense industry, wind energy, and automotive and transportation industries, the global core materials market is expected to witness significant growth during the forecast period. There are stringent regulations and laws being imposed by governments in many geographic regions regarding carbon emissions and sustainability in aerospace and automotive sectors. Thus, the demand for core materials is expected to grow gradually in many end use industries across various geographic locations.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=146879627

Lightweight foam core materials are expected to have a significant market share in the global core material market during the forecast period.

Foam is a lightweight and sturdy material; thus, it is the most preferred and economical core material solution in many end use industries. Foams have an excellent strength-to-weight ratio, and this material is easy to process and shape into complex structures. Due to these properties and exemplary mechanical strength and recyclability foam cores are used in various end use industries like wind energy, aerospace, and defense, marine, automotive and transportation, and others. Foam cores are used in sandwich structures to enhance overall structure and mechanisms of composites. Foam cores are manufactured from different thermoplastic and thermoset polymers, including PET, PVC, PU, PEI, SAN, and PMI. Foam core materials can be produced at different densities which range from 2lb/ft3 (30 kg/m3) to 20 lb/ft3 (300 kg/ m3) by changing the blowing agents, the ratio of ingredients in polymers, and adjusting the gas pressure. The foam that holds the maximum share in the foam core material market is the PET foam due to its excellent properties.

The wind energy end use industry is expected to hold the largest share in the global core materials market during the forecast period, in terms of volume and value.

Core materials are used extensively in the wind turbine blades as sandwich panels in the composite structures, hence wind energy is a major end-use industry in the core material market. The wind turbine blades are made by combining core materials and glass- reinforced polyester or epoxy. The core materials that are mainly used in wind energy industry are foam and balsa. Balsa foam core is made from end grain balsa, which is a natural product, this material is used in wind blades because of its excellent mechanical properties, such as high strength-to-weight ratio making them ideal for applications requiring strength and stiffness while being lightweight.

Get Sample Copy of this Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=146879627

The wind energy capacity is steadily increasing in many geographical regions owing to focus on sustainability and global climate change. Thereby, the demand from wind turbine blade manufacturers has experienced a surge, thereby raising the core material demand from the wind energy end use industry.

Asia Pacific region to account for the largest market share in the global core materials market during the forecast period.

Countries like India, China, South Korea, and Japan are rapidly developing countries in terms of product innovation and technological advances in many end use industries like wind energy, aerospace & defense, marine, automotive, construction & building, and other industries. The rapidly growing wind energy sector is a significant contributor to the core material market in the Asia Pacific region. These factors are expected to drive the core material market during the coming years in this region.

Key Players:

Prominent companies in the core material market include Gurit Holdings AG (Switzerland), Hexcel Corporation (US), 3A Composites (Switzerland), Evonik Industries AG (Germany), Armacell (Luxembourg), Diab Group (Sweden), The Gill Corporation (US), Euro Composites (Luxembourg), Changzhou Tiansheng New Materials Co., Ltd. (China), Plascore Inc. (US), and Toray Industries, Inc. (US).

Inquire Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=146879627

Gurit Holdings AG

In the core materials industry, Gurit Holdings AG is a well-known player, recognized for its creative ideas and steadfast dedication to quality. Gurit is a major worldwide provider of cutting-edge core materials and has a significant influence on a number of industries, including wind energy, construction, aerospace, marine, and automotive. Gurit has a long history that dates back several decades. Throughout that time, it has consistently pushed the limits of composite technology, gaining a reputation for dependability, quality, and innovative research and development. Gurit has been constantly working on its R&D to maintain its market share, for instance in January 2024 Gurit launched Gurit Kerdyn FR+. It is a PET recycled structural foam with Class C – EN13501 test and certification. It offers good compressive strength and stiffness. Additionally, Gurit® Kerdyn™? FR aligns with the Marine, Civil and Transportation markets’ needs for materials with good Fire, Smoke and Toxicity (FST) properties.

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Aashish Mehra

Email: Send Email

Phone: 18886006441

Address:1615 South Congress Ave. Suite 103, Delray Beach, FL 33445

City: Florida

State: Florida

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/core-material-market-146879627.html