Back EMF of Permanent Magnet Synchronous Motor

1. How is back EMF generated?

The generation of back electromotive force is easy to understand. The principle is that the conductor cuts the magnetic lines of force. As long as there is relative motion between the two, the magnetic field can be stationary and the conductor cuts it, or the conductor can be stationary and the magnetic field moves.

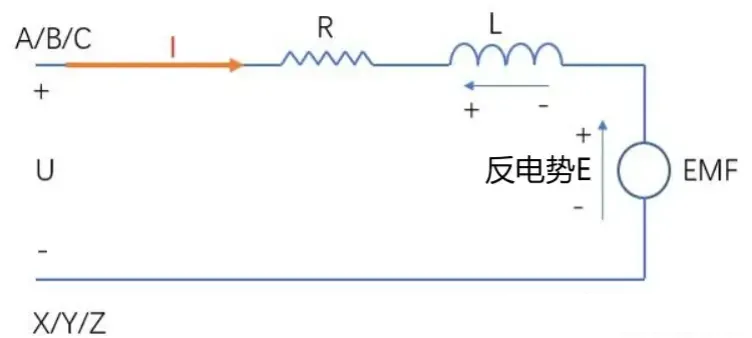

For permanent magnet synchronous motors, their coils are fixed on the stator (conductor) and permanent magnets are fixed on the rotor (magnetic field). When the rotor rotates, the magnetic field generated by the permanent magnets on the rotor will rotate, and will be cut by the coils on the stator, generating back electromotive force in the coils.Why is it called back electromotive force? As the name suggests, the direction of the back electromotive force E is opposite to the direction of the terminal voltage U (as shown in Figure 1).

Figure 1

2. What is the relationship between back EMF and terminal voltage?

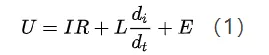

It can be seen from Figure 1 that the relationship between the back electromotive force and the terminal voltage under load is:

The back electromotive force test is generally carried out under no-load condition, without current and at a speed of 1000 rpm.Generally, the value of 1000rpm is defined as back-EMF coefficient = average back-EMF value/speed. Back-EMF coefficient is an important parameter of the motor. It should be noted here that the back-EMF under load is constantly changing before the speed is stable.From formula (1), we can know that the back electromotive force under load is smaller than the terminal voltage. If the back electromotive force is larger than the terminal voltage, it becomes a generator and outputs voltage to the outside. Since the resistance and current in actual work are small, the value of the back electromotive force is approximately equal to the terminal voltage and is limited by the rated value of the terminal voltage.

3. The physical meaning of back electromotive force

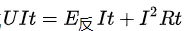

Imagine what would happen if the back EMF did not exist? From equation (1), we can see that without the back EMF, the entire motor is equivalent to a pure resistor, becoming a device that generates a lot of heat, which is contrary to the motor’s conversion of electrical energy into mechanical energy.In the electric energy conversion equation  ,UIt is the input electrical energy, such as the input electrical energy to a battery, motor or transformer; I2Rt is the heat loss energy in each circuit, which is a kind of heat loss energy, the smaller the better; the difference between the input electrical energy and the heat loss electrical energy,It is the useful energy corresponding to the back electromotive force

,UIt is the input electrical energy, such as the input electrical energy to a battery, motor or transformer; I2Rt is the heat loss energy in each circuit, which is a kind of heat loss energy, the smaller the better; the difference between the input electrical energy and the heat loss electrical energy,It is the useful energy corresponding to the back electromotive force .In other words, back EMF is used to generate useful energy and is inversely related to heat loss. The greater the heat loss energy, the smaller the achievable useful energy.Objectively speaking, back electromotive force consumes electrical energy in the circuit, but it is not a “loss”. The part of electrical energy corresponding to the back electromotive force will be converted into useful energy for electrical equipment, such as mechanical energy of motors, chemical energy of batteries, etc.

.In other words, back EMF is used to generate useful energy and is inversely related to heat loss. The greater the heat loss energy, the smaller the achievable useful energy.Objectively speaking, back electromotive force consumes electrical energy in the circuit, but it is not a “loss”. The part of electrical energy corresponding to the back electromotive force will be converted into useful energy for electrical equipment, such as mechanical energy of motors, chemical energy of batteries, etc.

It can be seen from this that the size of the back electromotive force means the ability of the electrical equipment to convert the total input energy into useful energy, which reflects the level of the electrical equipment’s conversion ability.

4. What does the magnitude of back electromotive force depend on?

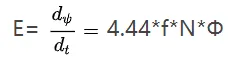

The calculation formula of back electromotive force is:

E is the coil electromotive force, ψ is the magnetic flux, f is the frequency, N is the number of turns, and Φ is the magnetic flux.Based on the above formula, I believe everyone can probably say a few factors that affect the magnitude of the back electromotive force. Here is an article to summarize:

(1) Back EMF is equal to the rate of change of magnetic flux. The higher the speed, the greater the rate of change and the greater the back EMF.

(2) The magnetic flux itself is equal to the number of turns multiplied by the single-turn magnetic flux. Therefore, the higher the number of turns, the greater the magnetic flux and the greater the back EMF.

(3) The number of turns is related to the winding scheme, such as star-delta connection, number of turns per slot, number of phases, number of teeth, number of parallel branches, and full-pitch or short-pitch scheme.

(4) Single-turn magnetic flux is equal to magnetomotive force divided by magnetic resistance. Therefore, the greater the magnetomotive force, the smaller the magnetic resistance in the direction of magnetic flux and the greater the back EMF.

(5) Magnetic resistance is related to air gap and pole-slot coordination. The larger the air gap, the greater the magnetic resistance and the smaller the back EMF. Pole-slot coordination is more complicated and requires specific analysis.

(6) Magnetomotive force is related to the residual magnetism of the magnet and the effective area of the magnet. The greater the residual magnetism, the higher the back EMF. The effective area is related to the magnetization direction, size and placement of the magnet and requires specific analysis.

(7) Residual magnetism is related to temperature. The higher the temperature, the smaller the back EMF.

In summary, the factors affecting back EMF include rotation speed, number of turns per slot, number of phases, number of parallel branches, full pitch and short pitch, motor magnetic circuit, air gap length, pole-slot matching, magnetic steel residual magnetism, magnetic steel placement and size, magnetic steel magnetization direction, and temperature.

5. How to select the size of back electromotive force in motor design?

In motor design, back EMF E is very important. If the back EMF is well designed (appropriate size, low waveform distortion), the motor is good. The back EMF has several major effects on the motor:

1. The magnitude of the back EMF determines the weak magnetic point of the motor, and the weak magnetic point determines the distribution of the motor efficiency map.2. The distortion rate of the back EMF waveform affects the motor ripple torque and the smoothness of the torque output when the motor is running.3. The magnitude of the back EMF directly determines the torque coefficient of the motor, and the back EMF coefficient is proportional to the torque coefficient.From this, the following contradictions in motor design can be obtained:a. When the back EMF is large, the motor can maintain high torque at the controller limit current in the low-speed operation area, but it cannot output torque at high speed, and even cannot reach the expected speed;b. When the back EMF is small, the motor still has output capacity in the high-speed area, but the torque cannot be achieved at the same controller current at low speed.

6. The positive impact of back EMF on permanent magnet motors.

The existence of back EMF is very important for the operation of permanent magnet motors. It can bring some advantages and special functions to the motors:a. Energy savingThe back EMF generated by permanent magnet motors can reduce the current of the motor, thereby reducing power loss, reducing energy loss, and achieving the purpose of energy saving.b. Increase torqueThe back EMF is opposite to the power supply voltage. When the motor speed increases, the back EMF also increases. The reverse voltage will reduce the inductance of the motor winding, resulting in an increase in current. This allows the motor to generate additional torque and improve the power performance of the motor.c. Reverse decelerationAfter the permanent magnet motor loses power, due to the existence of back EMF, it can continue to generate magnetic flux and make the rotor continue to rotate, which forms the effect of back EMF reverse speed, which is very useful in some applications, such as machine tools and other equipment.

In short, back EMF is an indispensable element of permanent magnet motors. It brings many benefits to permanent magnet motors and plays a very important role in the design and manufacture of motors. The size and waveform of back EMF depend on factors such as the design, manufacturing process and use conditions of the permanent magnet motor. The size and waveform of back EMF have an important influence on the performance and stability of the motor.

Anhui Mingteng Permanent Magnet Electromechanical Equipment Co., Ltd. (https://www.mingtengmotor.com/) is a professional manufacturer of permanent magnet synchronous motors. Our technical center has more than 40 R&D personnel, divided into three departments: design, process, and testing, specializing in the research and development, design, and process innovation of permanent magnet synchronous motors. Using professional design software and self-developed permanent magnet motor special design programs, during the motor design and manufacturing process, the size and waveform of the back electromotive force will be carefully considered according to the actual needs and specific working conditions of the user to ensure the performance and stability of the motor and improve the energy efficiency of the motor.

Copyright: This article is a reprint of the WeChat public number “电机技术及应用”, the original link https://mp.weixin.qq.com/s/e-NaJAcS1rZGhSGNPv2ifw

This article does not represent our company’s views. If you have different opinions or views, please correct us!

Media Contact

Company Name: Anhui Mingteng Permanent-Magnetic Machinery & Electrical Equipment Co., Ltd.

Email: Send Email

Country: China

Website: https://www.mingtengmotor.com/