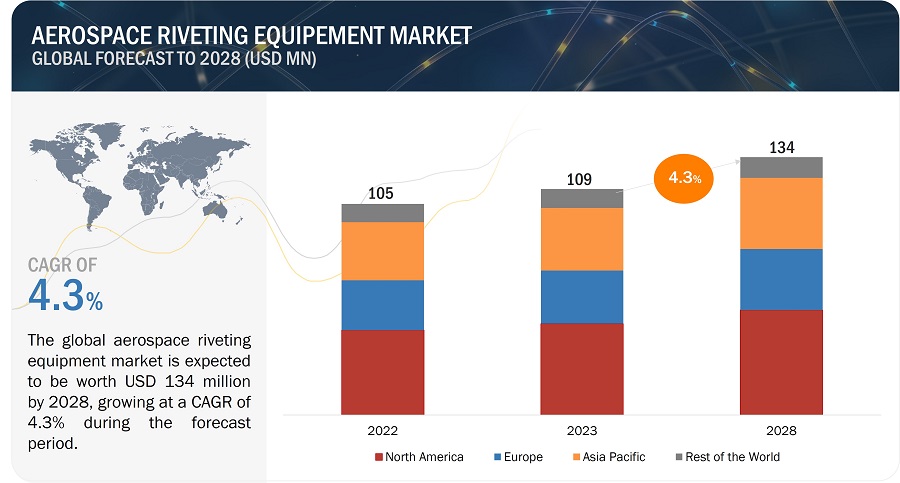

The report “Aerospace Riveting Equipment Market by End Use (OEM, MRO), Equipment Type (Pneumatic, Hydraulic, Electric), Mobility (Fixed, Portable), Technology (Automated, Manual), Rivet Type (Solid, Blind, Semi-tubular) and Region – Global Forecast to 2028” The Aerospace Riveting Equipment market is estimated to be USD 109 million in 2023 and is projected to reach USD 134 million by 2028, at a CAGR of 4.3 % from 2023 to 2028.

The aerospace riveting equipment market is witnessing sustained growth driven by several key factors. As global air travel continues to rise, there is a concurrent increase in demand for new aircraft production, propelling the need for aerospace riveting solutions. Moreover, the expanding fleet of commercial and military aircraft contributes significantly to the market’s growth, necessitating continuous maintenance, repair, and overhaul (MRO) activities. The industry’s emphasis on lightweight materials for enhanced fuel efficiency further boosts the demand for riveting, which plays a vital role in assembling modern aircraft structures.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=187704646

Browse 216 market data Tables and 40 Figures spread through 190 Pages and in-depth TOC on “Aerospace Riveting Equipment Market by End Use (OEM, MRO), Equipment Type (Pneumatic, Hydraulic, Electric), Mobility (Fixed, Portable), Technology (Automated, Manual), Rivet Type (Solid, Blind, Semi-tubular) and Region – Global Forecast to 2028”

View detailed Table of Content here – https://www.marketsandmarkets.com/Market-Reports/aerospace-riveting-equipment-market-187704646.html

Technological advancements in aerospace manufacturing, including automated riveting systems and innovative materials, contribute to increased efficiency and productivity. Stringent safety and regulatory standards drive the demand for high-quality riveting solutions, ensuring the structural integrity of aircraft. The aerospace riveting market is also influenced by global defense spending, with military aviation projects significantly contributing to the market’s dynamics.

Based on End Use, Original Equipment Manufacturer (OEM) segment is expected to acquire the highest market share during the forecast period.

The End-use segment has been segmented into Original Equipment Manufacturers (OEMs) and Maintenance, Repair, And Overhaul (MRO). Original Equipment Manufacturers (OEMs) are poised to acquire the highest market share in the aerospace riveting equipment market based on end-use for several compelling reasons. Firstly, as OEMs are responsible for the initial design and production of aircraft, they are the primary consumers of aerospace riveting equipment during the manufacturing phase. With the aerospace industry experiencing a surge in demand for new aircraft globally, OEMs are at the forefront of this growth, driving substantial demand for riveting equipment.

Secondly, OEMs often lead in technological innovation and design advancements, necessitating state-of-the-art riveting solutions to meet evolving manufacturing requirements. As aircraft designs incorporate lightweight materials for enhanced fuel efficiency, OEMs seek advanced riveting equipment that can effectively handle the assembly of these materials.

Based on Equipment Type, Pneumatic Riveting Equipment is projected to lead the market during the forecast period.

Pneumatic riveting equipment is poised to acquire the highest market share in the aerospace riveting equipment market due to several compelling factors. Pneumatic riveters leverage compressed air to perform the riveting process, offering a lightweight and cost-effective solution with high efficiency. In the aerospace industry, where weight considerations are critical for fuel efficiency, the lightweight nature of pneumatic riveting equipment becomes a significant advantage. Additionally, pneumatic riveting equipment provides a high level of precision, ensuring that rivets are securely fastened in complex aerospace structures. The reliability and consistency of pneumatic riveting contribute to the equipment’s widespread adoption in aircraft manufacturing, where precision and structural integrity are paramount.

Based on Mobility, the fixed equipment segment will grow at the fastest rate during the forecast period.

Based on Mobility the aerospace riveting market has been segmented into Fixed Equipment and Portable Equipment. Fixed riveting equipment offers unparalleled precision and consistency, ensuring the integrity and reliability of aerospace structures. This type of equipment is strategically positioned on the assembly line, facilitating the efficient and rapid riveting of components in a controlled environment. The high demand for precision and repeatability in aircraft assembly, particularly in the aerospace industry, favors the use of fixed riveting equipment, as it minimizes errors and enhances overall productivity.

Moreover, fixed riveting equipment is often equipped with advanced automation features, enabling seamless integration into modern manufacturing workflows. Automated riveting systems significantly reduce human error, enhance safety, and increase the overall speed of the assembly process.

Based on region, North America is expected to account for the largest market share during the forecast period.

North America is poised to acquire the highest market share in the aerospace riveting equipment market due to several key factors that collectively contribute to the region’s dominance. Firstly, North America is home to some of the world’s leading aerospace manufacturers, which drive substantial demand for cutting-edge riveting equipment. The region’s strong focus on technological innovation and research and development further positions it at the forefront of aerospace manufacturing, leading to increased adoption of advanced riveting technologies.

Moreover, the robust growth of the commercial aviation sector in North America, driven by a steady increase in air travel demand and the need for fleet modernization, plays a pivotal role in boosting the demand for aerospace riveting equipment. Additionally, the presence of a well-established aerospace ecosystem, comprising skilled labor, infrastructure, and supportive regulatory frameworks, enhances the overall competitiveness of the North American aerospace industry.

Key Players-

Ingersoll Rand (US), Cherry Aerospace (US), Brown Aviation Tool Company (US), Stanley Engineered Fastening (SEF) (US), LAS Aerospace Ltd. (UK) are some of the leading companies in the aerospace riveting equipment market. These companies have well-equipped manufacturing facilities and strong distribution networks across North America, Europe, Asia Pacific, and Rest of World.

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Aashish Mehra

Email: Send Email

Phone: 18886006441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL 60062

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/aerospace-riveting-equipment-market-187704646.html