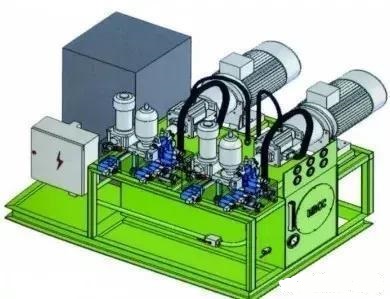

The servo system is an energy-saving and efficient hydraulic control method that uses a servo motor to drive the main transmission oil pump, reduce the control valve circuit, and control the hydraulic system slide. It is suitable for stamping, die forging, press fitting, die casting, injection molding, straightening, and other processes.

Compared with ordinary hydraulic presses, servo hydraulic presses have the advantages of energy saving, low noise, high efficiency, good flexibility, and high efficiency. The servo drive system can replace most existing ordinary hydraulic systems.

1. Energy saving:

(1) When the slider falls quickly or is stationary at the upper limit, the servo motor does not rotate, so no electric energy is consumed. The motor of the traditional hydraulic press still rotates at the rated speed. Still, it consumes 20% to 30% of the rated power (including the energy consumed by the motor cable, pump friction, hydraulic channel resistance, valve pressure drop, mechanical transmission connection, etc.).

(2) During the pressure holding stage, the speed of the servo motor of the servo hydraulic press only supplements the leakage of the pump and system. The speed is generally between 10rpm and 150rpm. The power consumed is only 1% to 10% of the rated power. Depending on the pressure-holding method, the actual power consumption of the traditional hydraulic press during the pressure-holding stage is 30% to 100% of the rated power.

(3) Compared with ordinary motors, the efficiency of servo motors is about 1% to 3% higher. This determines that servo-driven hydraulic presses are more energy-efficient.

2. Low noise:

The oil pump of a servo-driven hydraulic press generally adopts an internal gear pump, while the traditional hydraulic press generally adopts an axial piston pump. Under the same flow and pressure, the noise of the internal gear pump is 5dB~10dB lower than that of the axial piston pump.

When the servo hydraulic press is pressing and returning, the motor runs at rated speed, and its emission noise is 5dB~10dB lower than that of the traditional hydraulic press. When the slider is fast descending and stationary, the servo motor speed is 0, so the servo-driven hydraulic press has no noise emission.

During the pressure holding stage, due to the low motor speed, the noise of the servo-driven hydraulic press is generally less than 70dB, while the noise of the traditional hydraulic press is 83 dB~90 dB. After testing and calculation, under normal working conditions, the noise generated by 10 servo hydraulic presses is lower than that generated by an ordinary hydraulic press of the same specifications.

3. Less heat, reduced cooling cost, and reduced hydraulic oil cost:

The hydraulic system of the servo-driven hydraulic press has no overflow heat. When the slider is stationary, there is no flow and hydraulic resistance heat. The heat generated by its hydraulic system is generally 10% to 30% of that of a traditional hydraulic press. Due to the low heat generated by the system, most servo hydraulic presses do not need a hydraulic oil cooling system, and some with higher heat generation can be equipped with a low-power cooling system.

Since the pump is at zero speed and generates little heat most of the time, the oil tank of the servo-controlled hydraulic press can be smaller than that of a traditional hydraulic press, and the oil change time can also be extended. Therefore, the hydraulic oil consumed by the servo hydraulic press is generally only about 50% of that of a traditional hydraulic press.

4. High degree of automation, good flexibility, and high precision:

The pressure, speed, and position of the servo hydraulic press are fully closed-loop digital control. The high degree of automation and good precision. In addition, its pressure and speed can be programmable and controlled to meet various process needs.

5. High efficiency:

Through appropriate acceleration and deceleration control and energy optimization, the speed of the servo-controlled hydraulic press can be greatly improved, and the working cycle is several times higher than that of the traditional hydraulic press. It can reach 10/min~15/min.

6. Convenient maintenance:

Due to the elimination of the proportional servo hydraulic valve, speed control circuit, and pressure regulation circuit in the hydraulic system, the hydraulic system is greatly simplified. The cleanliness requirements for hydraulic oil are much lower than those of the hydraulic proportional servo system, which reduces the impact of hydraulic oil pollution on the system.

Zhengxi is a professional hydraulic press factory in China and provides the high-quality hydraulic press with servo hydraulic system. If you have any needs, contact us!

Media Contact

Company Name: Chengdu Zhengxi Hydraulic Equipment Manufacturing Co., Ltd.

Email: Send Email

Country: China

Website: https://www.zx-hydraulic.com/