Polylactic Acid (PLA) fiber is emerging as a groundbreaking material in the textile industry.

Derived from renewable plant resources, PLA fiber stands out for its biodegradability, biocompatibility, and impressive performance characteristics. It combines the advantages of natural fibers and chemically synthesized fibers,has a weak acidity similar to human skin, is naturally skin-friendly, antibacterial, anti-mite, and anti-allergic.

This article delves into the fascinating world of PLA fiber, exploring its origins, properties, categories, performance, and diverse applications. Through this examination, we aim to highlight the potential of PLA fiber as a sustainable solution in various industries,especially the textile industry.

Origins and Composition of PLA Fiber

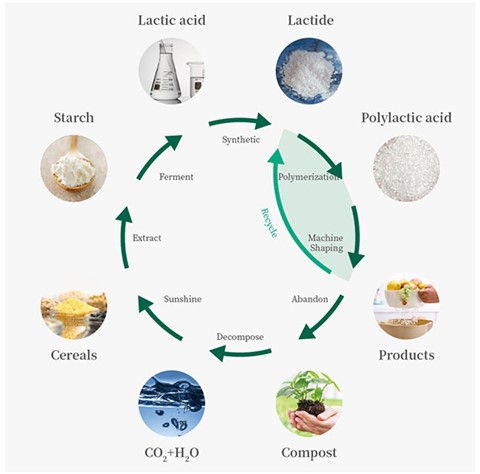

PLA fiber, full name polylactic acid fiber, is a synthetic fiber made from renewable plant resources (such as corn starch or sugar cane) through biotechnology processing.

PLA fiber is known as “eco-fiber,” its raw materials are sourced from renewable plant resources, which will reduce the consumption of non-renewable resources such as petroleum in the textile industry to a certain extent, and decrease the emission of greenhouse gases. Moreover, the production process of PLA fiber is also more low-carbon and environmentally friendly. From raw materials to waste, it can be decomposed into carbon dioxide and water in soil or seawater through microbial action, and it does not emit toxic gases when burned, thus not causing pollution.

PLA fiber is an eco-friendly alternative to traditional synthetic fibers.

Categories of PLA Fiber

Commonly used PLA fibers can be divided into two main categories: PLA short staples and PLA filament yarns.

1.PLA short staple

PLA short staple possesses commendable mechanical properties, including strength and elasticity. These fibers can be spun into pure products or blended with other materials such as cotton, wool, linen, lyocell, and modal fibers. Variants of PLA short staple include PLA staple, PLA super short cut staple, PLA Bi-component StaplePLA Three-dimensional Crimped Staple, colored spun yarns, and functional fibers. This versatility allows for extensive use across various textile applications.

2.PLA filament yarn

PLA filament yarn is a collection of fibers formed by stretching, twisting, or deforming multiple long monofilaments. A single strand of filament contains dozens of monofilaments, which is known as PLA composite filament. This can be spun into differentiated PLA fibers. At the same time, it also includes PLA monofilament, which, due to its unique properties, is widely used in fields such as medical sutures, fishing, and tea bags.

What is the performance of PLA fiber?

In addition to good mechanical properties and smooth breathability,PLA fiber also has the following characteristics:

1. Mechanical Properties

2.Biodegradability

3.Biocompatibility, Anti-allergy

4.Antibacterial and Anti-mite, Anti-mold and Anti-odor

5.Wearability

6. Other Properties

What applications can PLA fiber be used for?

PLA fiber’s unique properties make it suitable for a wide range of applications across different industries:

1、Sanitary Materials

PLA non-woven fabric has a smooth surface, does not absorb moisture, and has better fluidity, dryness, biocompatibility, and non-allergenicity, making it more suitable for people prone to allergies. It can be widely used in related fields of sanitary materials, such as the surface layer, diversion layer, and bottom layer of sanitary napkins and paper diapers, makeup remover cotton, wet wipes, face towels, membrane cloth, and other disposable sanitary products.

PLA fiber can meet the antibacterial requirements of disposable medical and sanitary products and solve the “white pollution” problem caused by disposable medical and sanitary products due to its biodegradability.

2、Apparel Fabrics

PLA fiber has physical properties similar to polyester/polyester materials, can be shaped, has good strength good dimensional stability, does not irritate the skin, is easy to wash and dry, and can also be functionalized by changing the process during spinning and adding other materials, such as moisture absorption and perspiration, UV protection, etc., thus developing uniquely advantageous apparel fabrics.

3、Home Textiles and Toy Fillings

a.Fillings for quilts, pillows: Represented by hollow PLA short fibers, it can be pure PLA or blended with other fibers, replacing existing polyester-related fillers.

b.Bedding fabrics (interwoven, blended, etc.): Can fully utilize its advantages of being skin-friendly, non-irritating, non-allergenic, overcoming the shortcomings of polyester/cotton fabrics, having better dimensional stability than all-cotton fabrics, and being easy to wash, dry, and care for.

4、Medical Supplies

Masks, protective clothing, medical gauze, bandages, sheets, and high-end antibacterial products, etc.

5、Agriculture

In agriculture, PLA fibers are used to create mulch films and seed blankets that protect crops while reducing the need for chemical fertilizers and pesticides. These products naturally decompose, enriching the soil instead of polluting it.

6、Other Applications

Packaging materials, sand barriers, filter bundles, decorative board adhesives, etc.

PLA fiber represents a significant advancement in sustainable textiles, offering a compelling combination of environmental friendliness and high performance.PLA fiber is contributing to a more sustainable and environmentally conscious world.

Media Contact

Company Name: ESUNfiber

Contact Person: Media Relations

Email: Send Email

Country: China

Website: https://www.esunfiber.net/