In the chemical production process, pressure not only affects the balance relationship and reaction rate of the production process, but also affects the important parameters of the system material balance. In the industrial production process, some require high pressure much higher than atmospheric pressure, such as high pressure polyethylene. Polymerization is carried out at a high pressure of 150MPA, and some need to be carried out at a negative pressure much lower than atmospheric pressure. Such as vacuum distillation in oil refineries. The high-pressure steam pressure of the PTA chemical plant is 8.0MPA, and the oxygen feed pressure is about 9.0MPAG. The pressure measurement is so extensive, the operator should strictly abide by the rules for the use of various pressure measuring instruments, strengthen daily maintenance, and any negligence or carelessness. All of them may incur huge damages and losses, failing to achieve the goals of high quality, high yield, low consumption and safe production.

The first section the basic concept of pressure measurement

- Definition of stress

In industrial production, the commonly referred to as pressure refers to the force that acts uniformly and vertically on a unit area, and its size is determined by the force-bearing area and the size of the vertical force. Expressed mathematically as:P=F/S where P is the pressure, F is the vertical force and S is the force area

- Unit of pressure

In engineering technology, my country adopts the International System of Units (SI). The unit of pressure calculation is Pa (Pa), 1Pa is the pressure generated by a force of 1 Newton (N) acting vertically and uniformly on an area of 1 square meter (M2), which is expressed as N/m2 (Newton/square meter) , In addition to Pa, the pressure unit can also be kilopascals and megapascals. The conversion relationship between them is: 1MPA=103KPA=106PADue to many years of habit, engineering atmospheric pressure is still used in engineering. In order to facilitate the mutual conversion in use, the conversion relations between several commonly used pressure measurement units are listed in 2-1.

| Pressure unit |

Engineering atmosphere Kg/cm2 |

mmHg |

mmH2O |

atm |

Pa |

bar |

1b/in2 |

|

Kgf/cm2 |

1 |

0.73×103 |

104 |

0.9678 |

0.99×105 |

0.99×105 |

14.22 |

|

MmHg |

1.36×10-3 |

1 |

13.6 |

1.32×102 |

1.33×102 |

1.33×10-3 |

1.93×10-2 |

|

MmH2o |

10-4 |

0.74×10-2 |

1 |

0.96×10-4 |

0.98×10 |

0.93×10-4 |

1.42×10-3 |

|

Atm |

1.03 |

760 |

1.03×104 |

1 |

1.01×105 |

1.01 |

14.69 |

|

Pa |

1.02×10-5 |

0.75×10-2 |

1.02×10-2 |

0.98×10-5 |

1 |

1×10-5 |

1.45×10-4 |

|

Bar |

1.019 |

0.75 |

1.02×104 |

0.98 |

1×105 |

1 |

14.50 |

|

Ib/in2 |

0.70×10-2 |

51.72 |

0.70×103 |

0.68×10-2 |

0.68×104 |

0.68×10-2 |

1 |

- Ways of expressing stress

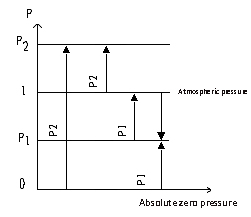

There are three ways to express pressure: absolute pressure, gauge pressure, negative pressure or vacuum.The pressure under absolute vacuum is called absolute zero pressure, and the pressure expressed on the basis of absolute zero pressure is called absolute pressureGauge pressure is the pressure expressed on the basis of atmospheric pressure, so it is exactly one atmosphere (0.01Mp) away from the absolute pressure. That is: P table = P absolutely-P big (2-2)Negative pressure is often called vacuum.It can be seen from the formula (2-2) that the negative pressure is the gauge pressure when the absolute pressure is lower than the atmospheric pressure. The relationship between absolute pressure, gauge pressure, negative pressure or vacuum is shown in the figure below:

Most of the pressure indication values used in industry are gauge pressure, that is, the indication value of the pressure gauge is the difference between absolute pressure and atmospheric pressure, so absolute pressure is the sum of gauge pressure and atmospheric pressure.

Section 2 Classification of Pressure Measuring InstrumentsThe pressure range to be measured in chemical production is very wide, and each has its particularity under different process conditions. This requires the use of pressure measuring instruments with different structures and different working principles to meet various production requirements. Different requirements. According to different conversion principles, pressure measuring instruments can be roughly divided into four categories: liquid column pressure gauges; elastic pressure gauges; electric pressure gauges; piston pressure gauges.

- Liquid column pressure gauge

The working principle of the liquid column pressure gauge is based on the principle of hydrostatics. The pressure measuring instrument made according to this principle has a simple structure, is convenient to use, has a relatively high measurement accuracy, is cheap, and can measure small pressures, so it is widely used in production. Liquid column pressure gauges can be divided into U-tube pressure gauges, single-tube pressure gauges, and inclined tube pressure gauges according to their different structures.

- Elastic pressure gauge

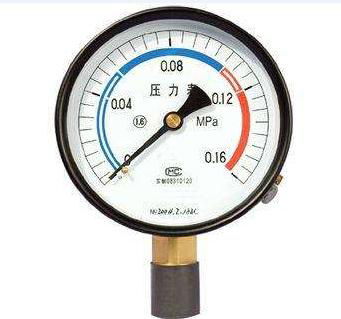

The elastic pressure gauge is widely used in chemical production because it has the following advantages, such as simple structure. It is firm and reliable. It has a wide measurement range, easy to use, easy to read, low in price, and has sufficient accuracy, and it is easy to make sending and remote instructions, automatic recording, etc.The elastic pressure gauge is made by using various elastic elements of different shapes to produce elastic deformation under the pressure to be measured. Within the elastic limit, the output displacement of the elastic element is in a linear relationship with the pressure to be measured. , So its scale is uniform, elastic components are different, pressure measurement range is also different, such as corrugated diaphragm and bellows components, generally used in low pressure and low pressure measurement occasions, single coil spring tube (abbreviated as spring tube) and multiple The coil spring tube is used for high, medium pressure or vacuum measurement. Among them, the single-coil spring tube has a relatively wide range of pressure measurement, so it is the most widely used in chemical production.

- Pressure Transmitters

At present, electric and pneumatic pressure transmitters are widely used in chemical plants. They are an instrument that continuously measures the measured pressure and converts it into standard signals (air pressure and current). They can be transmitted over long distances, and the pressure can be indicated, recorded or adjusted in the central control room. They can be divided into low pressure, medium pressure, high pressure and absolute pressure according to different measuring ranges.

Section 3 Introduction to Pressure Instruments in Chemical Plants

In chemical plants, Bourdon tube pressure gauges are generally used for pressure gauges. However, diaphragm, corrugated diaphragm and spiral pressure gauges are also used according to work requirements and material requirements. The nominal diameter of the on-site pressure gauge is 100mm, and the material is stainless steel. It is suitable for all-weather conditions. The pressure gauge with 1/2HNPT positive cone joint, safety glass and vent membrane, on-site indication and control is pneumatic. Its accuracy is ±0.5% of full scale. Electric pressure transmitter is used for remote signal transmission. It is characterized by high accuracy, good performance, and high reliability. Its accuracy is ±0.25% of full scale.The alarm or interlock system uses a pressure switch.

Section 4 Installation, Use and Maintenance of Pressure Gauges

The accuracy of pressure measurement is not only related to the accuracy of the pressure gauge itself, but also whether it is installed reasonably, whether it is correct or not, and how it is used and maintained.

- Installation of pressure gauge

When installing the pressure gauge, attention should be paid to whether the selected pressure method and location are appropriate, which has a direct impact on its service life, measurement accuracy and control quality.The requirements for pressure measurement points, in addition to correctly selecting the specific pressure measurement location on the production equipment, during installation, the inner end surface of the pressure pipe inserted into the production equipment should be kept flush with the inner wall of the connection point of the production equipment. There should be no protrusions or burrs to ensure that the static pressure is correctly obtained.The installation location is easy to observe, and strive to avoid the influence of vibration and high temperature.When measuring the steam pressure, a condensate pipe should be installed to prevent direct contact between high-temperature steam and the components, and the pipe should be insulated at the same time. For corrosive media, isolation tanks filled with neutral media should be installed. In short, according to the different properties of the measured medium (high temperature, low temperature, corrosion, dirt, crystallization, precipitation, viscosity, etc.), take corresponding anti-corrosion, anti-freezing, anti-blocking measures. A shut-off valve should also be installed between the pressure-taking port and the pressure gauge, so that when the pressure gauge is overhauled, the shut-off valve should be installed near the pressure-taking port.In the case of on-site verification and frequent flushing of the impulse tube, the shut-off valve can be a three-way switch.The pressure guiding catheter should not be too long to reduce the sluggishness of the pressure indication.

- Use and maintenance of pressure gauge

In chemical production, pressure gauges are often affected by the measured medium such as corrosion, solidification, crystallization, viscosity, dust, high pressure, high temperature, and sharp fluctuations, which often cause various failures of the gauge. In order to ensure the normal operation of the instrument, reduce the occurrence of failures, and extend the service life, it is necessary to do a good job of maintenance inspection and routine maintenance before production start-up. 1. Maintenance and inspection before production start-up: Before production start-up, pressure test work is usually performed on process equipment, pipelines, etc. The test pressure is generally about 1.5 times the operating pressure. The valve connected to the instrument should be closed during the process pressure test. Open the valve on the pressure taking device and check whether there is any leakage in the joints and welding. If any leakage is found, it should be eliminated in time. After the pressure test is complete. Before preparing to start production, check whether the specifications and model of the installed pressure gauge are consistent with the pressure of the measured medium required by the process; whether the calibrated gauge has a certificate, and if there are errors, they should be corrected in time. The liquid pressure gauge needs to be filled with working fluid, and the zero point must be corrected. The pressure gauge equipped with isolating device needs to add isolating liquid. 2. Maintenance and inspection of the pressure gauge when driving: During the production start-up, the pressure measurement of the pulsating medium, in order to avoid damage to the pressure gauge due to instantaneous impact and overpressure, the valve should be opened slowly and the operating conditions should be observed. For pressure gauges measuring steam or hot water, the condenser should be filled with cold water before opening the valve on the pressure gauge. When a leak in the instrument or pipeline is found, the valve on the pressure-taking device should be cut off in time, and then deal with it. 3. Daily maintenance of pressure gauge: The instrument in operation should be inspected regularly every day to keep the meter clean and check the integrity of the meter. If the problem is found, eliminate it in time.

Media Contact

Company Name: Sinomeasure

Email: Send Email

Phone: +86 18767163200

Country: China

Website: https://www.sinoanalyzer.com/