Double Disc grinding machine is a high-efficiency surface processing machine tool. It grinds two parallel end surfaces at the same time in one processing process. According to the structure, it can be divided into two types: horizontal type and vertical type. According to the feeding method, it can be divided into through type, turntable type, and reciprocating type.

Due to the high precision and high production efficiency of the grind products, they are widely used in many industries such as automobiles and motorcycles: bearings, and magnetic materials. Piston rings, valve washers, connecting rods, cross shafts, valve plates, hydraulic pump blades, rotors, stators, compressor vanes, bearing inner and outer rings and rollers in the automobile and motorcycle industry, magnetic rings, magnetic steel sheets in the electronics industry, Products of various materials such as graphite plates are suitable for processing.

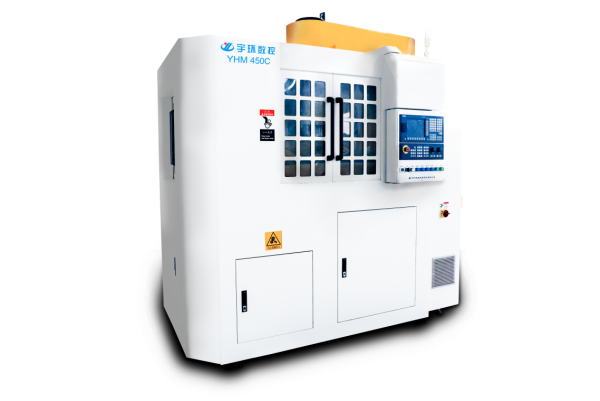

Overview of Double Disc Grinding Machine

In this century, with the rapid development of our country’s machinery industry, many imported parts have also been replaced by our own R&D and production. High-precision auto parts such as oil pump blades and compressor vanes can also be widely used in double-end grinding machines. , especially the size of the sliding vane for grinding with cubic boron nitride grinding wheel, can well ensure the technical requirements of rough and fine grinding of the product, the parallel difference is less than or equal to 0.005, and the flatness is less than or equal to 0.003. Equipped with an automatic feeding device, the production efficiency is improved, and the shift output reaches more than 70,000 pieces, which ensures the consistency of various dimensional requirements of the product, and has been widely used by domestic and foreign customers.

Main Feature of Double Disc Grinding Machine:

1. Adopt advanced numerical control system, stable and reliable performance, friendly man-machine interface.

2. In the processing of parts, the upper and lower planes are ground at the same time in layers, and it is equipped with a special automatic clamping mechanism, which has high processing efficiency, high parallelism between the upper and lower ends of the workpiece, and high verticality between the two ends and the central axis.

3. The grinding head feed adopts a special lead screw mechanism with high precision and high rigidity, and the feed accuracy reaches 0.001mm.

4. The main shaft of the grinding head is driven by variable frequency speed regulation, and the speed is 150-950r/min.

5. The feeding motor of the feeding tray is driven by an advanced servo motor, which can realize both C-shaped grinding and swing feed grinding. The speed of the feeding tray is 1-10r/min.

6. The modular design of the feeding turntable seat is fixed on the lower box body. The grinding wheel is loaded and unloaded from the left side of the lower box body. There is an upper and lower grinding wheel mechanism on the left side of the lower box body.

7. The machine tool is equipped with an online automatic detection system, which can automatically control the grinding quality in batches and improve work efficiency.

8. The box body adopts the upper and lower box structure form, the upper box body is supported by four corners, and the angle of the upper grinding head can be adjusted by adjusting the four corner supports, which is convenient, stable and reliable to adjust.

9. Dressing mechanism The upper and lower ends of the dressing shaft are fixedly connected to the box body and are driven by servo motors to ensure high dressing rigidity and smooth and reliable dressing grinding wheels.

10. The upper and lower casings and chassis of the machine tool are very firm and strong, the overall quality of the main machine is good, the rigidity is high, the grinding head runs smoothly, and the grinding workpiece is of high quality.

11. The machine is equipped with a visualization system that monitors the internal grinding.

About YUHUAN CNC MACHINE TOOL CO.,LTD

YUHUAN CNC MACHINE TOOL CO.,LTD is a public National Key High-tech Enterprise, which is a professional provider of precision grinding and technological solution for intelligent manufacturing. YUHUAN’s office and workshop covers about 20K square meters. YUHUAN has a modern production workshop, a Complex efficient grinding Laboratory, Computer Design Studio, has a variety of testing instruments and equipment over 30 sets of experimental facilities, and a variety of processing equipment over 60 sets.YUHUAN has about over 50 engineers R&D Team. Our main products output more than 1000Sets/Year.

Our main products are CNC grinding machine, CNC polishing machines, and intelligent equipment, they are widely applied to automotive, IT electronic, combustion engine, bearings, precision manufacturing, shipbuilding, military, aerospace, and other areas of the national economy.

Our cooperated customers: MAHLE, Apple USA (iPhone frame and screen), Foxconn (phone screen), Lens (phone screen), Porite (USA powder metallurgy), Federal Mogul (piston rings), ATG piston, Koyo bearings (Japan), NRB bearings, RIKEN (Thailand), LYC bearings (China top3), C&U bearings (China top 3), ILJIN (South Korea), CERATIZIT China, TATA India, etc.

Our company persists in the principle of “Achieving the Leading Manufacturing, Developing the National industry.” as our corporate goals and mission to become the leader of CNC grinding equipment and intelligent equipment industry.

Tel: 0086-731-81868967/ 86- 15386487286

Media Contact

Company Name: YUHUAN CNC MACHINE TOOL CO., LTD

Contact Person: Media Relations

Email: Send Email

Phone: 0086-731-81868967

Country: China

Website: www.yhcncmachine.com